Among various packaging forms, cosmetic tubes are very popular due to their functionality and cost-effectiveness. However, with so many materials, sizes, and designs to choose from, how can you choose the “perfect” tube for your product?

First, You Need to Understand the Characteristics of Your Own Products

Before choosing a cosmetic tube, you must have a deep understanding of your own products. The characteristics of the product determine the most critical factors in packaging selection.

The product’s physical viscosity and chemical compatibility have a direct impact on packaging options. The appropriate tube diameter is chosen based on whether the cream is thick, light, or fluid. Thick creams need a large hose for squeezing out. However, serums and eye gels need a smaller hose for accurate dosing.

Choose the Right Cosmetic Tube Material

The material used impacts the cost and look of the product. It also affects its protection and user experience. PE tube is the most popular and inexpensive option. Its soft texture and good strength make it suitable for many products, like facial cleansers and body lotions. ABL composite tube has an aluminum foil layer. This layer blocks light, air, and moisture. It is great for sunscreens, ointments, and products with sensitive ingredients. PBL composite tube combines high barrier capabilities with environmental benefits, and its all-plastic design facilitates recycling.

Cosmetic tube produced from plant-based materials like sugarcane and post-consumer recycled plastic are becoming more common. Choosing these environmentally friendly products not only successfully minimizes a brand’s carbon footprint, but also shows consumers that it is committed to environmental conservation.

Determine the Size and Capacity of the Cosmetic Tube

The size and capacity of the tube must be in line with your market positioning and product plan. The final capacity depends on the tube’s diameter. Common sizes are 19mm, 25mm, 35mm, and 50mm. The length also affects capacity. If your target market loves travel-size products, 15-30ml is the best option. If your target market prefers daily or family-sized items, 150-200ml is an acceptable size. Different capacities define the market you’re targeting, and selecting the appropriate size makes your brand more relatable to customers.

Design of Pipe Cover and Nozzle

The two most common tube cap types are screw caps and flip caps. Screw caps offer a better seal, keeping the product inside more stable, while flip caps are more popular and easier to use with one hand, making them very convenient.

The applicator determines the functionality of the product. For example, for eye cream, a cool metal massage head can provide a calming and soothing effect during use; for acne treatments, a roller ball head allows for targeted application. Choosing the right applicator and tube cap for each product is crucial. This is one of the factors that determine whether consumers will like your product, and a good choice will also make your product more unique.

Cosmetic Tube Process Design

These designs include the process of the tube body, the surface treatment of the tube body and the process of the tube cap.

Tube body printing process

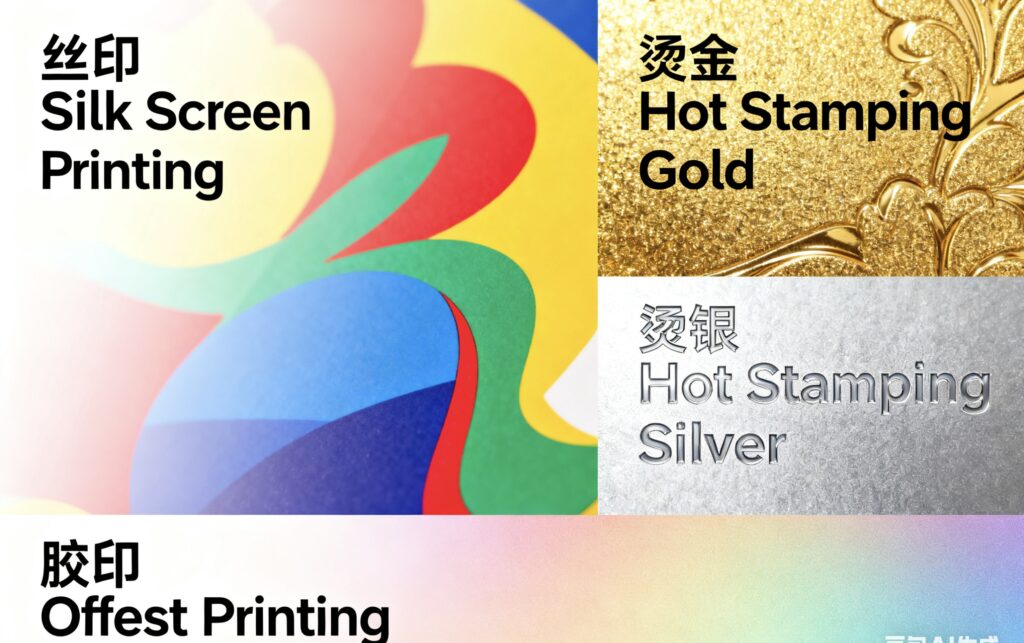

Tubes can be printed using silk-screen printing, offset printing, hot stamping (gold/silver), and labeling. Silk-screen printing creates a slightly raised, textured feel. Offset printing allows for multi-color printing in a single pass, resulting in high production speeds and suitable for mass production. Hot stamping creates a metallic sheen, adding a touch of luxury. Labeling offers design flexibility, but is susceptible to scratching and warping.

Tube surface treatment process

Tubes can be finished with glossy, matte, frosted, or pearlescent finishes. Glossy finishes create a more lustrous appearance and are easy to clean. Matte and frosted finishes offer a more textured feel and are also non-slip. Pearlescent finishes incorporate pearlescent powder into the soft tube, creating a pearl-like luster and are suitable for high-end skincare products.

Tube cover manufacturing process

Tube caps can be finished using electroplating or UV treatments. Electroplating creates a metallic finish and can be achieved in a variety of metallic colors, including bright gold, bright silver, and rose gold. Both UV and electroplating create a metallic finish, but differ in the process. Metals are more suitable for electroplating, but UV treatment is preferred for most products.

High-quality skincare tubes, from materials to design, ultimately influence consumer purchasing decisions and brand loyalty. Working with an experienced packaging supplier is the best approach. Their professional team will provide a personalized solution tailored to your needs and budget.